Cylinder Core Processing - Broaching Machines

Our automatic broaching machines enable fully automatic broaching of the profiles of cylinder cores. Depending on the technical requirements, we equip our systems with customised tool carriers that can even carry more than 900 broaching knives per machine.

- Large number of different broaching profiles.

- Tailor-made clamping devices to meet your requirements.

- Fast, safe and precise thanks to synchronous servo motors on all axes.

- Monitored broaching tools - efficient and low-failure with reduced tool costs.

- Wide range of core input and output options.

- Downstream machining possible

We build machines entirely according to your specifications and wishes - Here are a few examples...

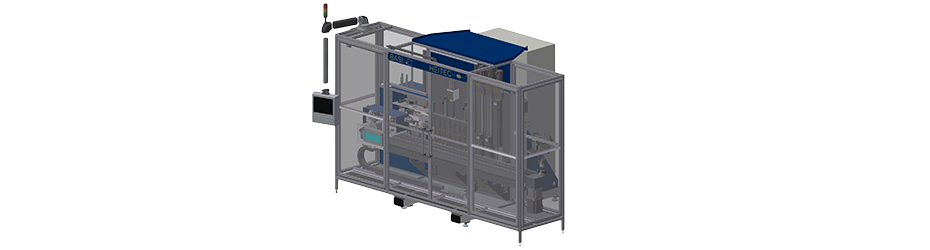

HeiCore BASIC

> more informations

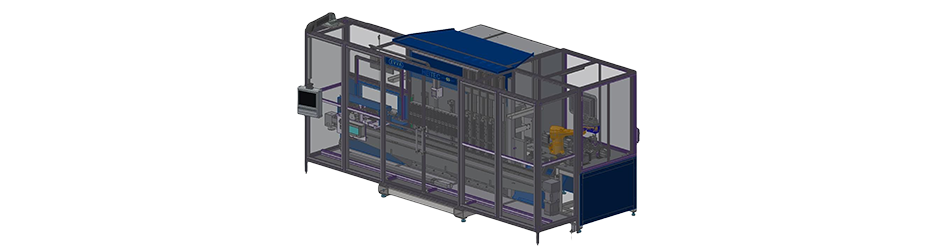

Complete fully automated core processing line with multiple input options, various post-processing and multiple output options.

Complete fully automated core processing line with magazine input and bulk material output.

Complete fully automated core processing line with manual input, deburring device and bulk material output.